Are you curious about the process of turning plastic waste into valuable resources through PE film pelletizing? In this article, we will delve into the fascinating journey of PE film pelletizing, exploring how waste materials can be transformed into high-quality pellets that can be used in various industries. Let’s take a closer look at this innovative and sustainable solution for managing plastic waste.

What is PE Film Pelletizing?

PE film pelletizing is a recycling process that involves converting post-consumer or post-industrial plastic film waste into granules or pellets. Polyethylene (PE) film is a common type of plastic material used in packaging, shopping bags, and other applications. Instead of letting these plastic films end up in landfills or oceans, they can be collected, cleaned, shredded, melted, and extruded into pellets.

The Importance of Recycling Plastic Film Waste

Plastic film waste poses a significant environmental challenge due to its non-biodegradable nature and widespread use in various products. By recycling PE film waste through pelletizing, we can reduce the amount of plastic pollution in the environment, conserve natural resources, and minimize the carbon footprint associated with producing new plastic materials.

The Pelletizing Process

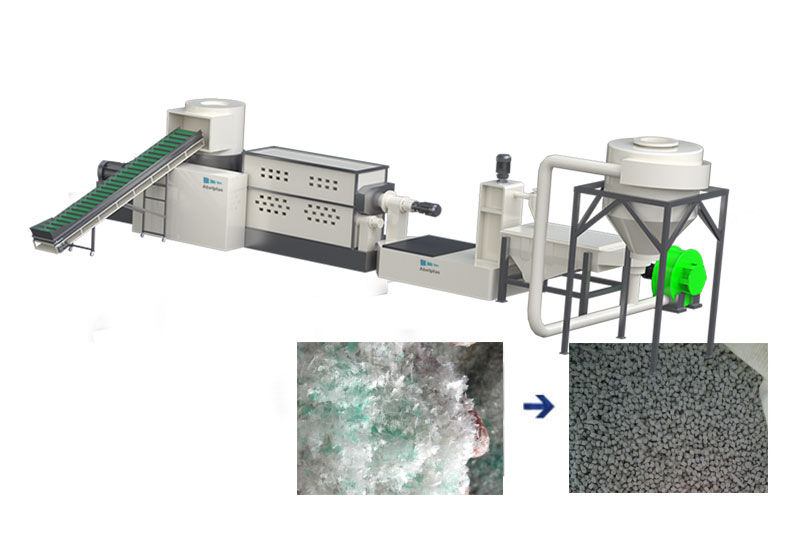

The PE film pelletizing process begins with the collection of plastic film waste from recycling centers, households, or manufacturing facilities. The collected waste is sorted, cleaned, and shredded into small pieces to remove impurities such as labels, adhesives, and contaminants.

Next, the shredded plastic film is fed into an extruder, where it is melted at high temperatures and transformed into molten plastic. The molten plastic is then forced through a die to form cylindrical strands, which are cooled and cut into pellets of uniform size. These pellets can be used as raw materials for manufacturing new plastic products.

Applications of PE Film Pellets

PE film pellets have a wide range of applications across various industries. These high-quality pellets can be used in the production of plastic films, bags, containers, pipes, and other plastic products. By using recycled PE film pellets, manufacturers can reduce their dependence on virgin plastic materials, lower production costs, and support sustainable practices.

Benefits of PE Film Pelletizing

There are several benefits associated with PE film pelletizing, including:

- Environmental Sustainability: By recycling plastic film waste, we can reduce the amount of waste sent to landfills and oceans, and conserve valuable natural resources.

- Cost-Effectiveness: Using recycled PE film pellets can help manufacturers save money on raw materials and production costs.

- Energy Efficiency: The pelletizing process consumes less energy compared to producing new plastic materials from scratch.

- Circular Economy: PE film pelletizing promotes a circular economy by closing the loop on plastic waste and creating a sustainable supply chain for plastic products.

Conclusion

In conclusion, PE film pelletizing offers a sustainable and efficient solution for managing plastic waste and creating valuable resources from what was once considered trash. By embracing this innovative recycling process, we can contribute to a cleaner environment, support sustainable practices, and reduce our impact on the planet. Let’s continue to explore new ways to turn waste into resources and build a more sustainable future for generations to come.

Remember, the journey from waste to resource starts with a single step towards recycling and reusing plastic materials. Join us in the movement towards a more sustainable and eco-friendly world through PE film pelletizing!